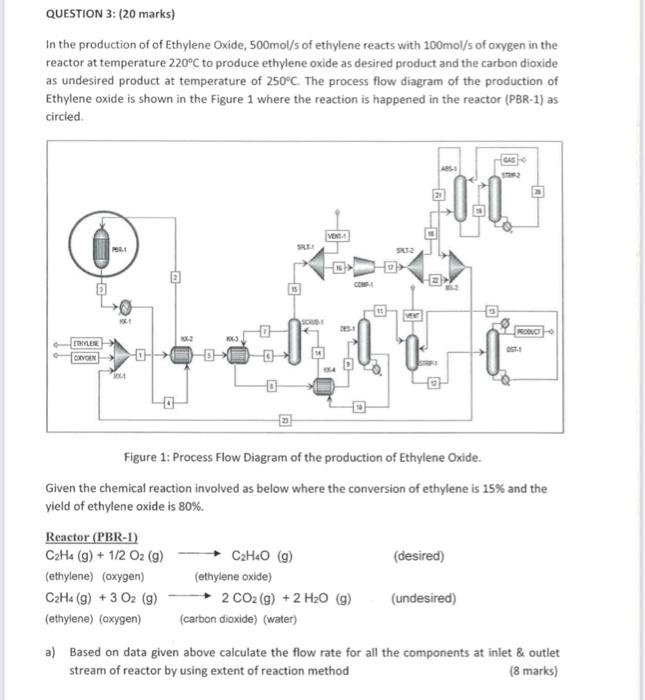

Ethylene Oxide Production Process Flow Diagram

50 Ethylene Oxide Production Process Flow Diagram Wr6i. Polyolefin PEPP EOEG Ethylene OxideEthylene Glycol Styrenics Resin GPPS HIPS SAN.

Figure 5 From No A 10 117 Ethylene Oxide Semantic Scholar

Component List for Hydrocarbon Reactant Stream.

Ethylene oxide production process flow diagram. Process Description 29 VI. The process flow diagram for the process can be found in Appendix A and is taken directly from the Aspen HYSYS model simulation. Now nearly all the worlds EO capacity is based on direct oxidation with oxygen generally preferred.

New Process Flow Diagram Based on Adsorptive Separation vorgelegt von MSc. Commerciallythemostimportantofthistype of reaction is the hydrolysis of ethylene oxide to ethyleneglycolAbout60ofthetotalethylene oxide production is converted into ethylene gly-col in this way. Global Mono-Ethylene Glycol Capacity by Process.

Air is compressed in C-701 and mixed with the feed. Water mix-ture is the principal feed to the process. Ethylene oxide itself is an excellent disinfectant sterilizing agent and fumigant when it is used as a non-explosive mixture with N2 or CO2.

180 KTA Ethylene production Process Flow Diagram of ERU Process Description of ERU. Tyr ethylene oxide unit was considered large whereas 10 years later plant sizes of 100000 150000 tyr were typical 116. Today some producers have plant capacities in excess of 250000 tyr.

A simplified process flow diagram for an EO process is shown in Figure 1. 3 is a simplified process flow diagram for an ethylene gly-cols manufacturing unit. ETHYLENE PROCESS FLOW DIAGRAMS Ethylene Steam Cracker Process Feed Furnace Section Feedstock Cracking Quench Separation Refrigeration Acid Gas Removal Compression Condensation Steam Generation Ethylene Propylene Recycle Streams Fuel Gas Streams Quench Compression Decontamination Separation.

Process Description Fresh ethylene Stream 1 and air Stream 2 are combined with a recycle stream containing. Ethylene oxide EO was initially manufactured using ethylene chlorohydrin as an intermediate but this route has been superseded by the direct oxidation of ethylene with air or oxygen. The by-products of this process are mostly water and carbon dioxide2.

Ethylene ProcessToyo Engineering Corporation. It is an extremely versatile chemical intermediate. PROCESS DESCRIPTION WITH BLOCK FLOW DIAGRAM AND DESCRIPTION OF QUALIFIED PROPERTY ETHYLENE OXIDE PROCESS DESCRIPTION Ethylene oxide EO C 2H 4O is a colorless flammable gas or liquid.

The raw material is ethylene which may be assumed to be pure. The mixed feed is heated vaporized and superheated in a heat. The first step in the production of ethylene is to take the feedstock and crack it into ethylene and other various products in a furnace.

Process flow diagram of ethylene plant. Production of Ethylene Oxide Process Description Figure 1 is a preliminary process flow diagram PFD for the ethylene oxide production process. Therefore such compounds are often used to produce derivatives.

Furnace The two primary feedstocks for ethylene production are naphtha and natural gas ethane propane butane etc. Energy Balance and Utility Requirements 37 VII. Air-Based Direct Oxidation Process.

Finished purified ethylene oxide EO or an EO. Process Flow Diagram and Material Balances 17 V. In the normal operating range for the catalyst 225 to 275C lower single-pass conversion favors ethylene oxide production.

Vietnam von der Fakultät III Prozesswissenschaften der Technischen Universität Berlin zur Erlangung des akademischen Grades Doktor der Ingenieurwissenschaften - Dr-Ing -. Ethylene Production by Oxidative Coupling of Methane. By dubaikhalifas On Aug 24 2021.

Decrease SizeIncrease Size Ethylene and oxygen are fed to a multi-tubular reactor forming EO. Production of Ethylene Oxide Production process is based on a cat. However most of it is converted into other products such as fibers foils bottles plasticizers solvents antifreezes cosmetics etc.

MEG is injected at the inlets of the gas-to-gas exchangers and the propane chiller. A schematic flow diagram of the air-based ethylene oxide process. According to the licenser the process is able to achieve EO-to-EG converstion and selectivity near 100 leading to production of MEG only.

Pure ethylene oxide as well as a waste liquid stream and vent gas streams. Relationship between customer values and the two main ethylene production processes ethanol dehydration and hydrocarbon cracking. The features of the Lummus ethylene process are the use of an SRT furnace Short.

Ethylene compressed oxygen and recycle gas are mixed and fed to a multi-tubular catalytic reactor. The purpose of the Low Pressure Ethylene Recovery ER Unit is to remove impurities found in the FCC offgas and to recover the ethylene for use in the downstream EBSM units to make styrene monomer. General ethylene furnace schematic I.

Ethylene Oxide EO Production and Manufacturing Process. High capacity SRT-X with ethylene production capacity of up to 300 KTA and high selectivity. Xuan Son Nghiem aus Hanoi S.

Ethylene oxide and compoundscontaining labile hydrogen atoms. This feed is mixed with re-cycled water eg.

Question 3 20 Marks In The Production Of Of Chegg Com

Https Www Ugr Es Tep028 Pqi Descargas Industria 20quimica 20organica Tema 5 Oxido Etileno A10 117 Pdf

Optimal Reaction Concept And Plant Wide Optimization Of The Ethylene Oxide Process Sciencedirect

Technology Profile Ethylene Oxide Production From Ethylene Chemical Engineering Page 1

Figure 3 1 From A Simulation Model Of A Reactor For Ethylene Oxide Production Semantic Scholar

Petrochemical Chemical Industry Mogas

Process Flow Diagram Of The Cebc Process Table 3 Lists The Simulation Download Scientific Diagram

Process Flow Diagram Of The Cebc Process Table 3 Lists The Simulation Download Scientific Diagram

Armadillo Engineering Ceng 403 Project 2

Ethylene Oxide Is A Chemical Used To Make Ethylene Chegg Com

Biomass To Ethylene B2 Processdesign

Ethylene Glycol Production Chemical Engineering

Biomass To Ethylene B2 Processdesign

Http Www Diquima Upm Es Old Diquima Docencia Tqindustrial Docs Ox Etileno Pdf

Improved Process Design And Optimization Of 200 Kt A Ethylene Glycol Production Using Coal Based Syngas Sciencedirect

Figure B 6 1 Unit 700 Ethylene Oxide Process Flow Diagram Download Scientific Diagram

Http Www Diquima Upm Es Old Diquima Docencia Tqindustrial Docs Ox Etileno Pdf

0 Response to "Ethylene Oxide Production Process Flow Diagram"

Posting Komentar